GeBrik®

Composition:

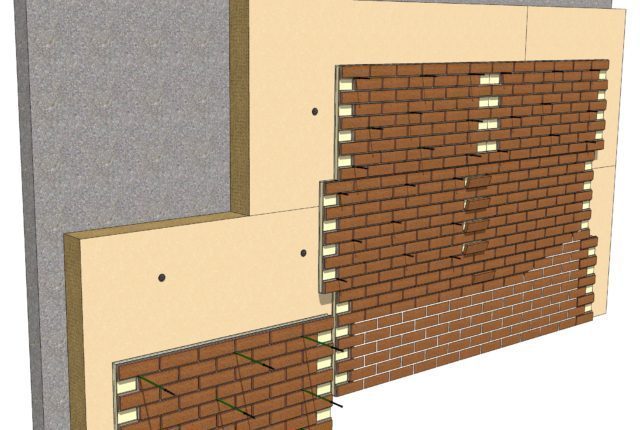

GeBrik® is a factory prefabricated cladding system consisting of a layer of brickslips set in a polyurethane foam board (PUR).

The manufacturing process, where the brickslips are placed “in the mould”, results in high quality prefabricated elements with a perfect bond between brickslips and insulation.

The panels are mechanically fixed with screws through the joints. The system of glued-in-place connection brickslips and the final pointing gives a finish similar in every respect to traditional masonry, but allows for a wider use than traditional masonry.

Application:

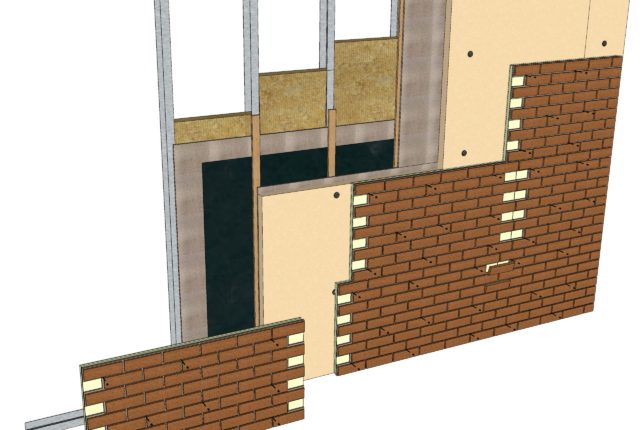

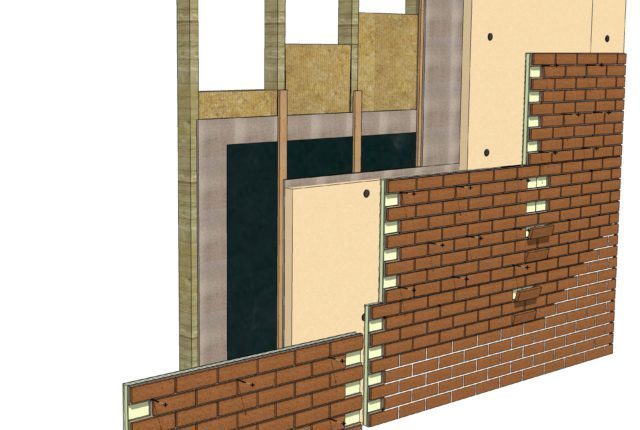

The system is intended for covering facades and can be used on various types of buildings and substrates such as :

– Concrete, masonry, clay block, sand-lime block, tiles or natural stone

– Wood composite panels for timber frame building cladding

– Metal panels (steel or aluminium) for cladding metal-framed buildings

The system is also suitable for all kinds of additional insulation materials (PUR, PIR, Resol, XPS, EPS, glass wool, rock wool, …)

The maximum range of application is determined by the wind resistance, the light exposure, the shape, the dimensions of the construction and the location on the façade.

The GeBrik® system does not require a firebreak. It ensures that flames do not spread through the façade.

Panel dimensions:

The panels are faced with a layer of natural brickslips (15 to 20mm) which is encapsulated into a rigid PUR insulation board.

The panels vary in length from 1000 to 1500 mm and width from 500 to 750 mm.

The standard thickness of the panels is 60mm. The weight of the board varies between 26 and 35 kg per square metre, with a maximum of 60kg/m².

Colors:

Our range includes more than 800 types of bricks and we work with all the major brickslips manufacturers.

If you have a special wish… then you have come to the right place.

We give you the space to make personal choices for your project.

Insulation:

The insulation material is a polyurethane foam (polyol + isocyanate) expanded with n-pentane in a mould to the size of the panel.

Fixings:

The screws and plugs for the different types of substrates, supplied by ISOSYSTEMS, are made of galvanised steel and have a countersunk TORX head.

Various screws are available for fixing to wood, composite and metal substrates.

Finishes:

The foam chamber between the panels provides a circular bond and a seamless insulation layer. This will be filled with a single-component polyurethane foam of the brand “ISOSYSTEMS”.

The connecting brickslips between the panels are treated with “ISOSYSTEMS” brand adhesive mortar.

System performance:

| Reaction to fire class determined in accordance with NBN EN ISO 13501-1 | B-s1, d0 |

| Watertightness (resistance to driving rain) | no infiltration |

| Resistance to water vapour diffusion | 107 -249 µ |

| Resistance to heat-rain & heat-cold cycles followed by freeze-thaw cycles | compliant |

| Wind load resistance | 4500 Pa - 8,5 mm |

| Bonding strength of the brickslips in the foam | >0,10 N/mm² |

| Pull-trough strength of fixings | >500N/fixing point |

| Pull-through strength of ISO-fixings | >600N/fixing point |

| Impact resistance | class 1 |

| Thermal conductivity (λD) | 0,029 W/m.K |

| Fire spread resistance (Lepir2/ BR135/ Fire105) | compliant |

Reaction to fire class determined in accordance with NBN EN ISO 13501-1

- B-s1, d0

Watertightness (resistance to driving rain)

- no infiltration

Resistance to water vapour diffusion

- 107 -249 µ

Resistance to heat-rain & heat-cold cycles followed by freeze-thaw cycles

- compliant

Wind load resistance

- 4500 Pa - 8,5 mm

Bonding strength of the brickslips in the foam

- >0,10 N/mm²

Pull-trough strength of fixings

- >500N/fixing point

Pull-through strength of ISO-fixings

- >600N/fixing point

Impact resistance

- class 1

Thermal conductivity (λD)

- 0,029 W/m.K

Fire spread resistance (Lepir2/ BR135/ Fire105)

- compliant